Table of Contents

Introduction:

Electricity is an extremely handy and useful form of energy. It plays an ever-growing role in our modern industrialized society. The electrical power systems are highly non-linear, extremely huge, and complex networks. Such electric power systems are unified for economic benefits, increased reliability, and operational advantages. They are one of the most significant elements of both national and global infrastructure, and when these systems collapse it leads to major direct and indirect impacts on the economy and national security. A power system consists of components such as generators, lines, transformers, loads, switches, and compensators. However, widely dispersed power sources and loads are the general configurations of modern power systems.

For many applications, it is necessary to disable a DC-DC converter when its input voltage goes outside a specified range. A transformer is a static electrical device used in electric power systems to transfer power between circuits through the use of electromagnetic induction. Transformers are devices that transfer energy from one circuit to another using a common magnetic field. When an alternating current flows in a conductor, a magnetic field exists around the conductor. If another conductor is placed in the field created by the first conductor such that the flux lines link the second conductor, then a voltage is induced into the second conductor. The use of a magnetic field from one coil to induce a voltage into a second coil is the principle on which transformer theory and application are based. Transformers range in size from thumbnail-sized used in microphones to units weighing hundreds of tons interconnecting the power grid. A wide range of transformer designs are used in electronic and electric power applications. Transformers are essential for the transmission, distribution, and utilization of electrical energy.

Block diagram explanation:

Power supply unit:

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

Temperature sensor:

Thermistors are thermally sensitive resistors whose prime function is to exhibit a large, predictable, and precise change in electrical resistance when subjected to a corresponding change in body temperature. Negative Temperature Coefficient (NTC) Thermistors exhibit a decrease in electrical resistance when subjected to an increase in body temperature and Positive Temperature Coefficient (PTC) thermistors exhibit an increase in electrical resistance when subjected to an increase in body temperature.

Buffers:

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface.

Drivers:

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified.

Relays:

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Indicator:

This stage provides a visual indication of which relay is actuated and deactivated, by glowing respective LED or Buzzer.

Methodology:

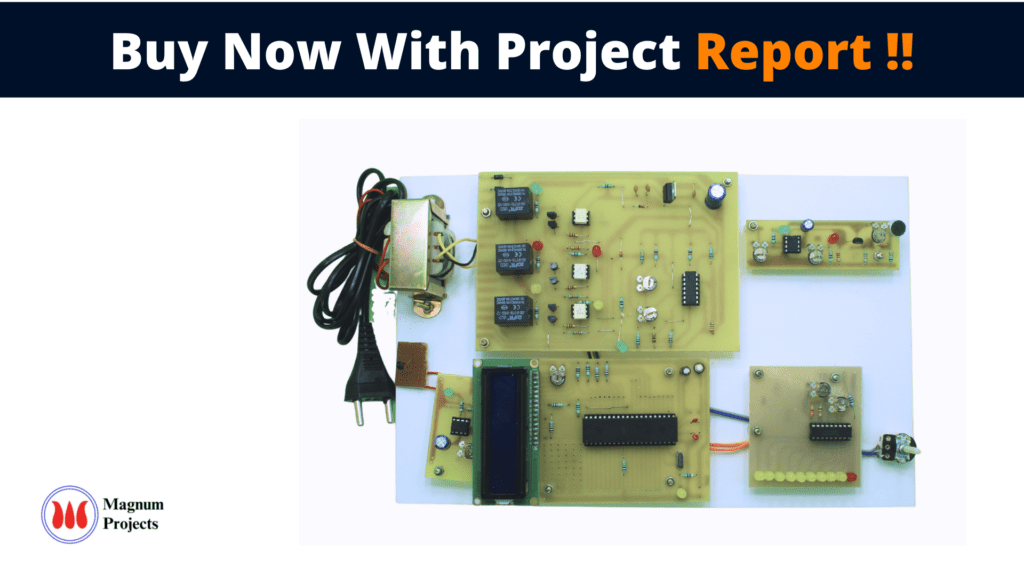

Distributed transformers are prone to damage due to overload or huge current flows through the internal winding of the transformer. The transformers are to be monitored very cautiously during these situations. The proposed system consists of a monitoring unit that is connected to the distribution transformer to monitor the same. We have designed a system based on a Microcontroller that monitors and displays the condition of the transformer and motor. Mic will sense the noise in the transformer and motor and it has a Resistive load to monitor the pressure of the load and a temperature sensor to sense temperature. The Microcontroller will display the sensed parameter result on an LCD.

Advantages:

- All the components required are easily available.

- It is accurate [Errors are nullified] & precise as it is Digital.

- Low power consumption.

- Less hardware involved and Cost Efficient.

- Automatically controlled & Easy to use.

- Unnecessary wastage of electricity can be controlled to a greater extent.

- Eliminate or at least minimize runoff

- By implementing this project we can safeguard the transformers

- Without interrupting the operation we can deliver the power

- By proper maintenance, we can maintain the life to the maximum time

- Easy for the lineman to debug the issue at a faster rate

Disadvantages:

- In this project usage of relays leads to consuming more power.

- One-time investment.

- The electricity network only (not gas) concerns both distribution and transmission levels.

Applications:

- This project can be implemented in homes, Schools, Colleges, Companies, etc…

- Where we have to reduce the workload of humans, former and to sense the parameters like temperature and conductivity there we can implement this project.

- Used in small and big industries, shopping malls, multiplexes, cinema halls, hostels, hotels, etc

- This system can be used to monitor and control the home appliances