Table of Contents

Introduction:

MOBILE robot navigation has stood as an open and challenging problem over the last few decades. Despite the significant advances in this field, researchers have yet to reach a comfortable level of satisfaction. To date, most of the robot navigation algorithms proposed in the literature are either tailored toward particular structured environments or driven by an overwhelming degree of computational complexity. In some cases, the hardware needed to implement the algorithm can be more costly than the robot itself. This makes the practical realization of such algorithms in most real-world robotic systems questionable. This paper contributes to the efforts of developing practical, modular, and easy-to-implement robot navigation algorithms that are both cost and computationally effective. The proposed algorithm takes advantage of the emerging Radio Frequency IDentification (RFID) technology and a fuzzy logic controller (FLC) to guide the robot to navigate in its working space given these shortcomings, researchers shifted their interest to vision-based navigation to improve the robot position estimation by tracing the visual features in the environment and using them as landmarks. This measurement usually returns bearing to the visual features only, with no a priori knowledge of the landmark positions. Nevertheless, such a technique also has its disadvantages, which include the lack of information depth, complex image processing algorithms with high computational burden, and its dependence on the working environment. This problem can be alleviated by adopting behavior-based navigation systems, as they can incorporate a relatively large number of sensors, making them suitable for navigation in unstructured environments. However, relying on numerous sensors makes the system vulnerable to drifts and cumulative errors. To overcome this shortcoming, some researchers used artificial landmarks to compensate for these errors. For example, in some studies, RFID tags were placed in particular locations in the workspace, and the robot was equipped with an RFID reader to communicate with the tags to estimate its position In cases where the RFID systems were applied to mobile robot systems, they were mainly used for robot localization but not directly for navigation. In this paper, we describe a novel navigation technique in which RFID tags are mounted in fixed locations in the 3-D space. The tags are used to define the desired trajectory of the robot. The aim of the navigation algorithm is then to make the robot navigate along the virtual lines on the ground, linking the orthogonal projection points of the tags on the ground. Unlike other studies of this kind reported in the literature, there is no restriction on where the tags should be mounted. For indoor applications, they can be mounted on the ceiling, whereas outdoors, they can be mounted, for example, on posts. A two-antenna RFID reader is mounted on the robot to communicate and determine the robot’s relative position concerning the tags.

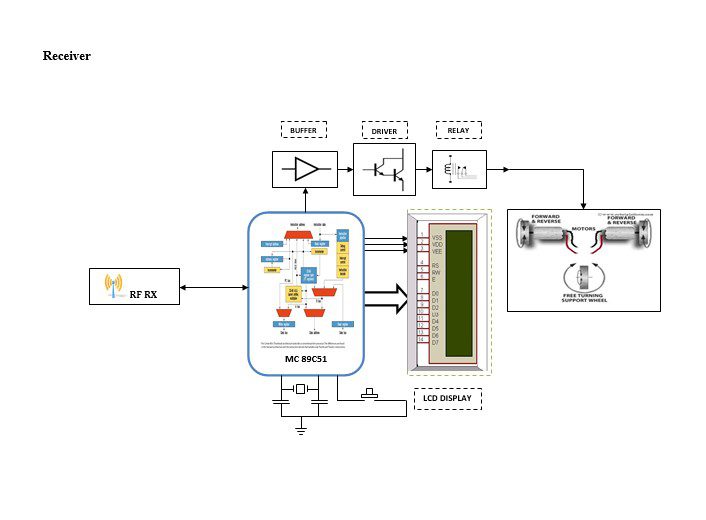

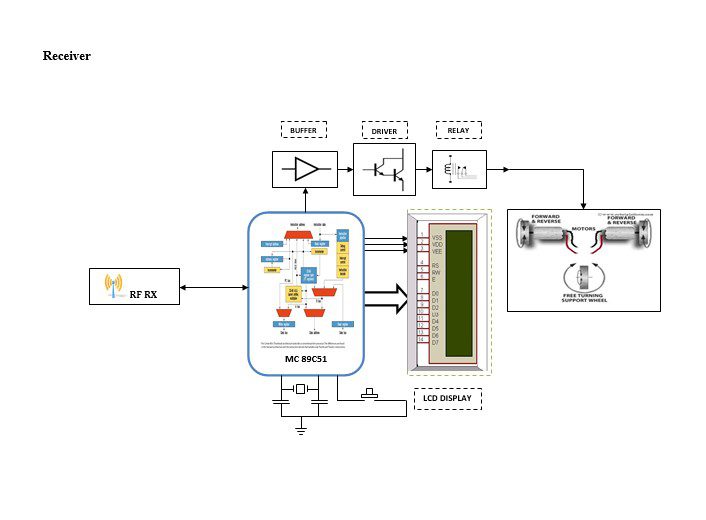

Block diagram explanation:

Power supply unit:

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

MSP 430 Controllers:

Here the MSP 430 is used to check the password which has been entered from the keyboard. If the password is correct it generates the output accordingly. The output of this section is connected to Buffer & Driver unit for further processing.

RF transmitter:

This is a 4-channel Radio Frequency Transmitter specially tuned with its RF Receiver part in carrier frequency. Each zone is set with one channel and transmits its presence to the moving vehicle’s RF Receiver unit.

RF receiver:

This is also a 4-channel RF Receiver specially tuned with its counterpart RF Transmitter in carrier frequency. When a vehicle enters any zone that zones RF signals are received by this unit. Thus depending upon the channel signals it receives from the transmitting end the channel output of the RF Receiver goes HIGH. This HIGH signal is fed to the MSP chip through Buffer & Driver and Switching stage for further processing.

Buffers

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface.

Drivers

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified.

Relays

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Methodology:

A block diagram which is shown above is divided into two parts that are transmitter and receiver. The transmitter part is which is in the base station and can be controlled by an authorized person consider in the border area head. First, to control the receiver part which is the robot he should enter the password which is highly secured in this system we are using MSP 430 as a controller device at the transmitting end. Once the authorized person enters the password he can control the receiver end which is at the military border the wireless communication takes via RF which we use of 4-channel for the prototype.

Advantages:

- Wireless control

- Surveillance System.

- Vehicle Navigation with the use of 3G technology.

- Takes in use of mobile technology which is almost available everywhere.

- This wireless device has no foundation of range and can be controlled as far as a network of cell phone

Disadvantages:

1. RFID is not secure

Applications:

- Scientific

- Military and Law Enforcement

- Search and Rescue

- Recreation and Hobby