Table of Contents

Intoduction:

LPG, first produced in 1910 by Dr. Walter Snelling is a mixture of Commercial Propane and Commercial Butane having saturated as well as unsaturated hydrocarbons. Because of the versatile nature of LPG, it is used for many needs such as domestic fuel, industrial fuel, automobile fuel, heating, illumination, etc and the demand for LPG is on an exponential rise day by day. The liquefied petroleum gas is finding wide usage in homes, industries, and automobiles as fuel because of its desirable properties which include high calorific value, produces less soot, produces very less smoke, and does not cause much harm to the environment. Natural gas is another widely used fuel in homes. Both burn to produce clean energy, however, there is a serious threat of their leakage. The gases being heavier than air do not disperse easily and may lead to suffocation when inhaled; also the leaked gases when ignited may lead to an explosion. The number of deaths due to the explosion of gas cylinders has been increasing in recent years. There is a need for a system to detect and also prevent leakage of LPG. Before the development of electronic household gas detectors in the 1980s and 90s, gas presence was detected with a chemically infused paper that changed its color when exposed to the gas. Since then, many technologies and devices have been developed to detect, monitor, and alert the leakage of a wide array of gases. Today, booking an LPG cylinder is now just a text message away. Petroleum companies have launched a customer-friendly service called as IVRS (Interactive Voice Response) technique for their customers. The proposed system reduces the customer burden. Nowadays, a big problem in our houses is to refill the cylinder. Most of the time people hand over the old cylinder to the delivery men without knowing the exact quantity of the gas left in it. LPG weighing machine is used to overcome this problem. It will monitor and display the quantity of gas level in the cylinder when the gas level reaches below the threshold limit.

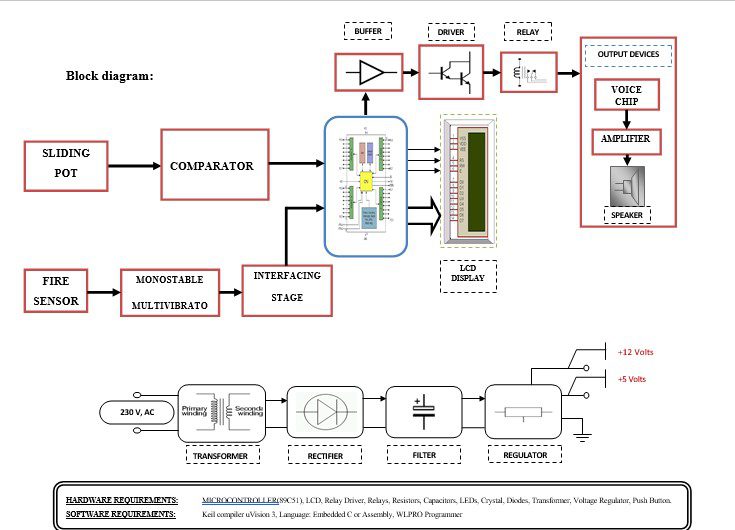

Block diagram explanation:

Power supply unit:

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

Buffers:

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface.

Drivers:

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified.

Relays:

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Indicator:

This stage provides a visual indication of which relay is actuated and deactivated, by glowing respective LED or Buzzer.

Methodology:

The block diagram consists of two parts. One part is implemented to monitor the Gas Cylinder Weight and gives a voice announcement if the cylinder is going to be empty. Another part is to monitor the temperature, if the temperature exceeds this module will give voice announcements like fire detected. Here sliding pot is used to monitor the Gas Cylinder Weight and Thermistor is used as a fire sensor. In both conditions, this module will give a voice announcement about the things going on via Microcontroller(89C51) and interfacing stage (Buffer, Driver, and Relay). Microcontroller is used to check whether fire detected or the gas cylinder is going to empty and activates the voice recorder to provide proper information about the things going on.

Advantages:

- No Manual attention is needed.

- More flexible.

- Gives information about the gas cylinder weight and fire alert.

Disadvantages:

- Damage to the sensor cannot be detected.

- One-time investment cost.

- This is a time-consuming process for the maintenance department with highly skilled manpower.

Applications:

- This module can be implemented in Homes, Schools, and Company cafeterias.

- Industries and canteens.

- This module can be used to weigh different kinds of products also.