Table of Contents

Introduction:

Data acquisition plays an important role in the field of modern industry control. DAQ (Data Acquisition) is simply the process of bringing a real-world signal, such as a voltage, into the computer, for processing, analysis, storage, or other data manipulation. A Physical phenomenon represents the real-world signal you are trying to measure. To optimize the characteristics of a system in terms of performance, handling capacity, and cost, the relevant subsystem can be combined. Analog data is generally acquired and transformed into digital form for processing, transmission, and display. In this sophisticated world, every activity is getting atomized with the help of embedded concepts. All the way so far we have seen that any controlling of parameters, utilizing natural resources for circuit operation, preventing the devices from electric disorders, optimizing, etc…, is carried out with analog instruments. So we decided to develop an electronic aid which is Data Acquisition System Using an ARM controller.

In automation and instrument building we often are confronted by the necessity to precisely control the illumination of light, the rotational speed of a fan, controlling the devices depending on the detection of human being present in the room or not, and device switching using remote. Their illumination can be controlled by switching ON the number of LED as per requirement; depending on the room temperature speed of the FAN or conditioning unit of AC can be controlled as a function of applied voltage. It monitors the surrounding environment and electrical conditions depending on those parameters the embedded system will control the operation of the devices. Like, if the room temperature is increased more than the desired temperature the system will automatically control the speed of the fan.

This particular machine is an Embedded one, so it is highly efficient and it is also packed with highly interactive and user-friendly components with a wide application. This Cost effective unit is surely a good example of technology being used for a very productive purpose. The unit is flexible to use and also renders the best of features found in some of the commercially available units.

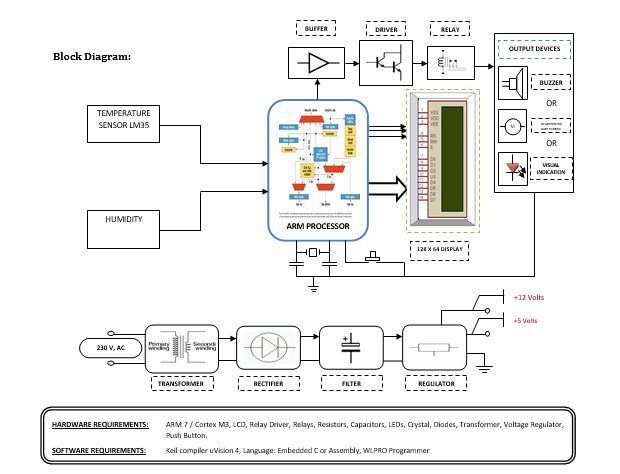

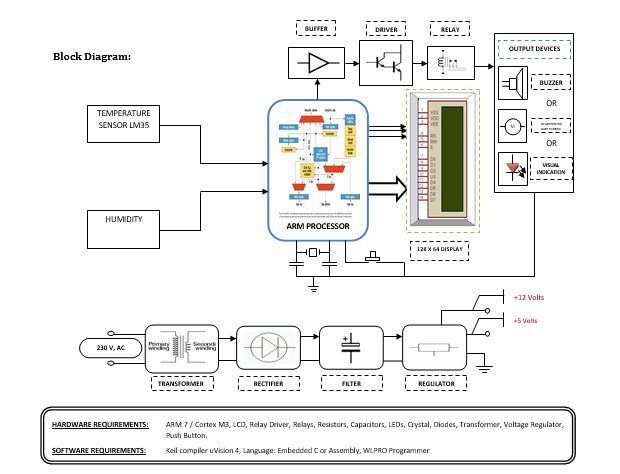

Block diagram explanation

Power supply unit

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

Temperature Sensor LM 35:

LM35 is a precision IC temperature sensor with its output proportional to the temperature (in oC). The sensor circuitry is sealed and therefore it is not subjected to oxidation and other processes. With LM35, temperature can be measured more accurately than with a thermistor. It also possesses low self-heating and does not cause more than 0.1C temperature rise in still air.

The operating temperature range is from -55°C to 150°C. The output voltage varies by 10mV in response to every oC rise/fall in ambient temperature, i.e., its scale factor is 0.01V/ oC.

Humidity Sensor:

Humidity measurement instruments usually rely on measurements of some other quantity such as temperature, pressure, mass, or a mechanical or electrical change in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices use temperature of condensation (the dew point), or changes in electrical capacitance or resistance to measure humidity differences.

ARM processor

ARM is computer processor-based RISC architecture. A RISC-based computer design approach means ARM processors require significantly fewer transistors than typical processors in average computers. This approach reduces costs, heat, and power use. The low power consumption of ARM processors has made them very popular:

The ARM architecture (32-bit) is the most widely used in mobile devices, and the most popular 32-bit one in embedded systems.

Buffers

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface

Drivers

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified

Relays

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Buzzer:

A buzzer or beeper is an audio signaling device, which may be mechanical, electromechanical, or piezoelectric. Typical uses of buzzers and beepers include alarm devices, timers, and confirmation of user input such as a mouse click or keystroke.

DC motor:

A DC motor relies on the fact that magnet poles repel and unlike magnetic poles attract each other. A coil of wire with a current running through it generates an electromagnetic field aligned with the center of the coil. By switching the current on or off in a coil its magnetic field can be switched on or off or by switching the direction of the current in the coil the direction of the generated magnetic field can be switched 180°.

Indicator:

This stage provides a visual indication of which relay is actuated and deactivated, by glowing respective LED or Buzzer.

Methodology:

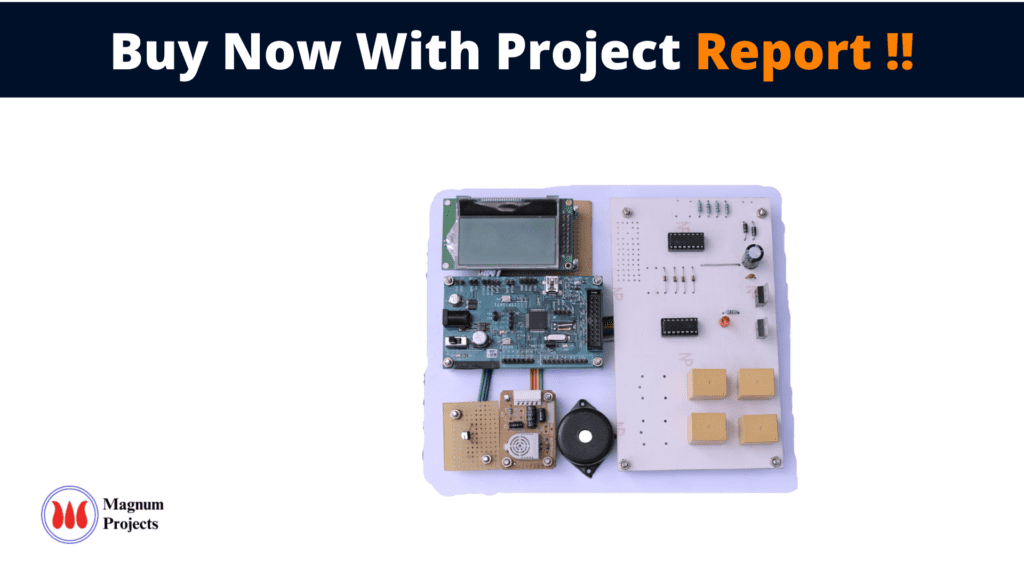

This project is developed to store data and then retrieve the data and to reduce the workload of human beings. The main modules in this project are Temperature Sensor LM 35, Humidity Sensor, ARM controller unit with LCD, and output device.

This whole model can be placed anywhere. This model has two Sensors as an input device to sense the Temperature and Humidity of the environment. This module continuously monitors the environment of the place where it is placed. If the temperature increases then that signal will be given to the ARM controller. The ARM controller analyses the signal and it will activate the buzzer to indicate fire has been detected. Likewise, the humidity sensor will sense the humidity of the environment, and that signal will be given to the ARM controller. The ARM controller analyses the signal and it will activate the DC motor to increase or decrease the speed of a Fan. The Fan speed should depend on the humidity of the environment.

Advantages:

- All the components required are easily available.

- It is accurate [Errors are nullified] & precise as it is Digital.

- It is much more economical compared to other analog systems.

- Manual errors can be avoided to some extent.

- Automatically controlled & Easy to use.

- Unnecessary wastage of electricity can be controlled to a greater extent.

Disadvantages:

- In this project usage of relays leads to consuming more power.

Applications:

- This project can be implemented in homes, Schools, Colleges, Companies, etc…

- Where we have to reduce the workload of humans there we can implement this project.