Table of Contents

Introduction:

Nowadays, home automation using wireless communication is replacing the wired system which was difficult to set up. Wireless sensor networks (WSNs) have been utilized all over the world. The wireless sensor networks can be used in many consumer and industrial applications, such as machine health monitoring and control, environment and habitat monitoring, biomedical health monitoring, home automation, traffic control, natural disaster relief, and seismic sensing. Wireless sensor networks in the home are easy to establish without using cables and offer greater coverage. Several studies say that Wireless sensor networks are a cost-effective solution for collecting, receiving, and transmitting data. Home/office automation consists of security, heating, ventilation, air-conditioning (HVAC), lighting control, access control, and electrical appliance control.

Under a smart home environment, numerous sensors i.e. detectors for temperature, smoke, gas leakage, fire, PIR and light, etc., and communication devices can be utilized for connection throughout the house, capable of monitoring and detecting the events. The input from these sensors can be used to alert the owner of any intrusion done in an unauthorized way or control home appliances such as lighting, air conditioner. Thus, maintaining seamless connectivity between devices and the main controller is very crucial A lost connectivity can jeopardize the security of the home. There are many related works concerning the design of home/office automation control using wireless sensor networks.

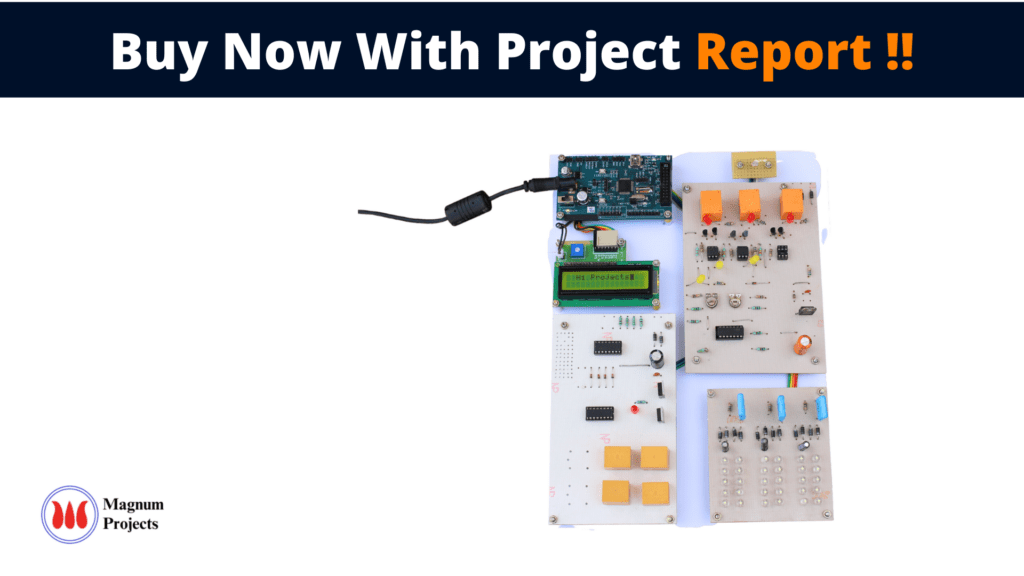

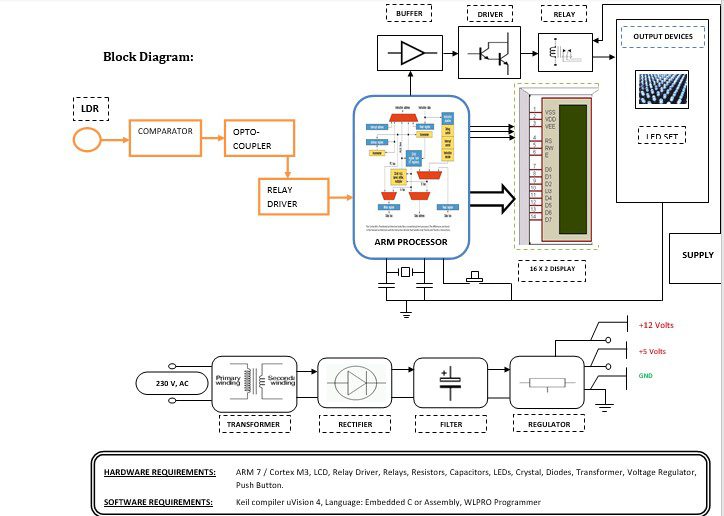

Block diagram explanation:

Power supply unit:

This section needs 2 voltages +12 and +5 Volts, as working voltages Hence specially designed power supply is constructed to get a regulated power supply.

Comparator:

Here comparator is used to compare the i/p from LDR and compares the light intensity and generates the output accordingly. The o/p of this comparator is then applied to the ARM controller via the Relay driver unit.

ARM 7:

The heart of the system is the microcontroller which will access the data. In our project, ARM7 is used. The ARM7 which we used for our project is LPC2148 (PHILLIPS) ARM7 is a high-performance, low-cost, low-power consumption RISC processor. For a variety of areas, such as embedded control, multimedia, DSP, and mobile applications, ARM architecture is the first RISC microprocessor designed for the low-budget market. The embedded operating system will be subject to certain restrictions. But because of its low price, reliability, and other factors, it is widely used in various industrial controllers.

Buffer:

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface.

Driver:

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified.

Relay:

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Sensor

Light Dependent Resistor

Light-dependent resistor (LDR) is a resistor whose resistance decreases with increasing incident light intensity; in other words, it exhibits photoconductivity. It can also be referred to as a photoconductor or CdS device, from “cadmium sulfide,” which is the material from which the device is made and that exhibits the variation in resistance with light level. A photoresistor is made of a high-resistance semiconductor. If light falling on the device is of high enough frequency, photons absorbed by the semiconductor give bound electrons enough energy to jump into the conduction band. The resulting free electron (and its hole partner) conduct electricity, thereby lowering resistance.

Methodology:

The output of the LDR is connected to Comparator this lighting model is controlled by Comparator which receives the commands from the LDR. The output of the LDR varies according to the presence of light from the environment. Depending on the presence of light from the environment the illumination of light is controlled by the ARM controller.

Applications:

1. Light-saving system

2. Counter-dependent automatic switching system of the room.

3. Camera Exposure Control

4. Auto Slide Focus – dual cell

5. Photocopy Machines – density of toner

6. Colorimetric Test Equipment

7. Densitometer

8. Electronic Scales – dual cell

9. Automatic Gain Control – modulated light source

10. Automated Rear View Mirror

Advantages & Disadvantages:

Advantages:

1. Unnecessary wastage of electricity can be controlled to a greater extent.

2. Maximum power can be saved.

3. Selectable Sensitivity, Sensitivity can be adjusted to match installation requirements.

4. Wide supply voltage range: 3.0V to 15V in COMPARATOR.

Disadvantages:

- The high capital expenditure required to invest in automation (an automated system can cost millions of dollars to design, fabricate, and install).

- A higher level of maintenance is needed than with a manually operated machine, and a generally lower degree of flexibility in terms of the possible products as compared with a manual system.