Table of Contents

Introduction:

The safe production level of a coal mine is still low, especially in recent years, disasters in coal mines occur frequently, which lead to the great loss of possession and life, and the safety problems of the coal mine have gradually become the focus that the nation and society concern on. The disasters in coal mine happening are due to the complexity of the mine environment and the variety of work conditions of coal mines, so it is very necessary to monitor the mine working environment. The various environmental parameters of mine safety monitoring and controlling system, such as methane, carbon monoxide, temperature, oxygen, and so on, are currently using traditional cable transmission. Thus truly mine methane; carbon monoxide gas accumulation area mechanized mining face, such as the dead gob cable security parameters cannot be monitored, so they cannot predict the alarm. With a variety of products for the current diversity of coal mine safety and underground coal mining process variability space, the mine safety wireless network should be compatible with existing mine safety systems with data transmission functions and has good flexibility, scalability, and self-set of network capabilities. As the mine has its special applications require simple sensor network protocols, network easy, self-organization, and self-healing ability.

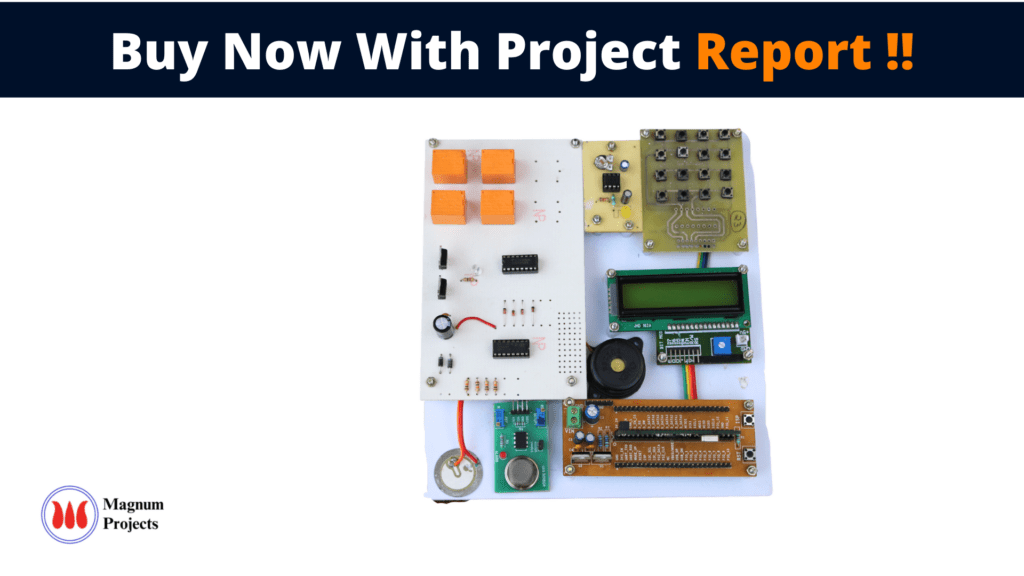

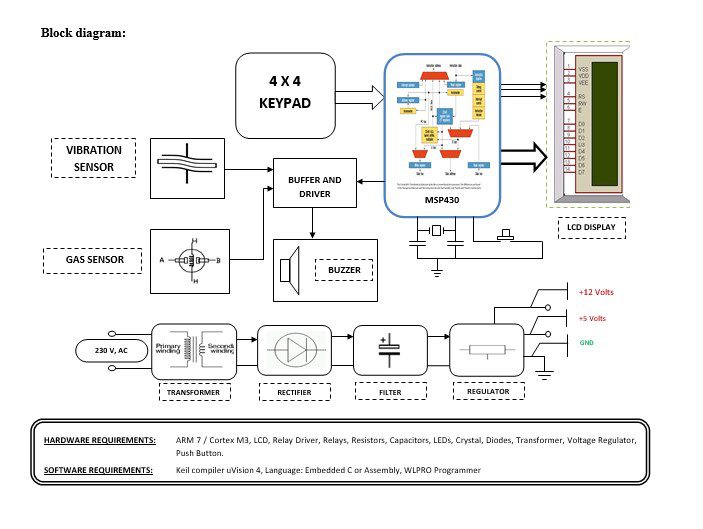

Block diagram explanation:

Power supply unit:

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

MSP 430 Controllers:

Here the MSP 430 is used to check the password which has been entered from the keyboard. If the password is correct it generates the output accordingly. The output of this section is connected to Buffer & Driver unit for further processing.

Buffers

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface.

Drivers

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified.

Relays

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Gas sensor

Explosion due to gas leakage is one of the most potential hazards in mining or industry. A mixture of gas with air is explosive within the range of 5-14% by volume of gases. The Gas Sensor Modules are designed to allow an MSP 430 to determine when a preset gas level has been reached or exceeded. The type of gas detected depends on which module you are using. Interfacing with these sensors is done through A MQ3. The sensor modules are intended to provide a means of comparing gas sources and being able to set an alarm limit when the source becomes excessive.

Vibration detector:

Based on piezoelectric technology various physical quantities can be measured; the most common are pressure and acceleration. For pressure sensors, a thin membrane and a massive base is used, ensuring that an applied pressure specifically loads the elements in one direction. For accelerometers, a seismic mass is attached to the crystal elements. When the accelerometer experiences a motion, the invariant seismic mass loads the elements according to Newton’s second law of motion . On account of its inertia, a mass exerts compressive forces on a ring-shaped piezo-ceramic element in time with the oscillation which generates the excitation. Within the ceramic element, these forces result in charge transfer to the ceramic, and a voltage is generated between the top and bottom of the ceramic element. This voltage is picked off using contact discs – in many cases, it is filtered and integrated – and made available as a measuring signal. To route the vibration directly into the sensor, vibration sensors are securely bolted to the objection in which measurements take place.

Methodology:

A general block diagram of the proposed scheme is given in Figure. In the Module there is a Vibration & poisonous gas Detector, when the vibration or & poisonous gas is detected it gives the signal to the MSP 430 controller, then the controller will generate the output that is fed to buffer IC 4050, buffer stores, and given to the driver IC 2003 in driver current will amplify and voltage will invert with the help of Darlington pair circuit of driver IC to drive the relay. Then the signal is given to the output load buzzer for indication purposes.

Advantages:

- More useful in remote areas.

- Firing events more help full to save.

- This project we can operate easily

- Can be used globally

Disadvantages:

1. under the mine the personal safety of staff problem.

2. Personnel positioning problem.

Applications:

- This project can be implemented in gas Industries.

- It is used in the mining of coal & other materials.

- It is used in municipal gas distribution.

- This project can be used in Military applications.

- It is used in nuclear power stations.