Table of Contents

Introduction:

The safe production level of a coal mine is still low, especially in recent years, disasters in coal mines occur frequently, which lead to the great loss of possession and life, and the safety problems of the coal mine have gradually become the focus that the nation and society concern on. The disasters in coal mine happening are due to the complexity of the mine environment and the variety of work conditions of coal mines, so it is very necessary to monitor the mine working environment. The various environmental parameters of mine safety monitoring and controlling system, such as methane, carbon monoxide, temperature, oxygen, and so on, are currently using traditional cable transmission. Thus truly mine methane, and carbon monoxide gas accumulation area mechanized mining face, such as the dead gob cable security parameters cannot be monitored, so they cannot predict the alarm. With a variety of products for the current diversity of coal mine safety and underground coal mining process variability space, the mine safety wireless network should be compatible with existing mine safety systems with data transmission functions and has good flexibility, scalability, and self-set of network capabilities. As the mine has its special applications require simple sensor network protocols, network easy, self-organization, and self-healing ability.

Zigbee is a wireless communications technology, with a short distance, safe and reliable, you can use Zigbee technology to collect the various parameters of the terminal transmitted to the sensor on the tunnel gateway, and then use a wired data transmission to the gateway on the ground central control computer, by computer analysis and comparison of the data to assess the security situation in the Mine. To achieve the target location underground, environmental and other parameters of the remote collection, can provide a scientific basis for relief. Underground mine environment, the complexity of the power consumption, interference immunity and so have more stringent requirements. In, an agent-based wireless local positioning system with ZigBee technology is proposed, mainly for factory-level applications. A cost-effective ZigBee-based wireless mine supervising system with early-warning intelligence on methane, temperature, and humidity in mining areas is proposed. Again, another article presents the development of a system integrated into a ZigBee network to measure the whole human body vibration, for the persons exposed to a vibratory environment. ZigBee specification is incorporated by many manufacturers in their devices because of its low power consumption and decreasing development cost. In the work presented here, Digit makes the ZIGBEE24 product used here for transmitting and receiving data wirelessly.

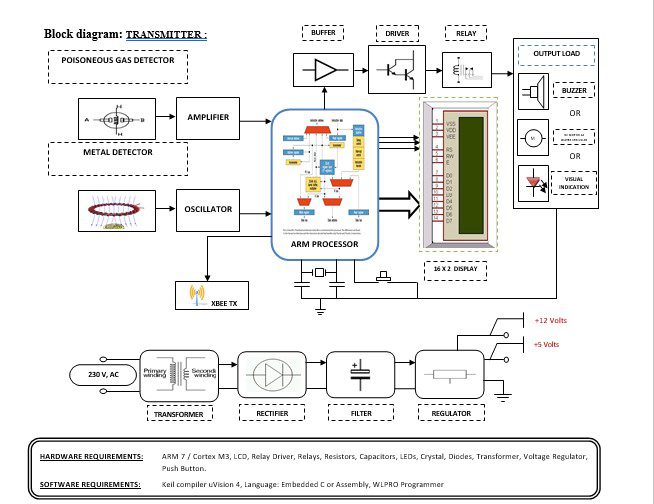

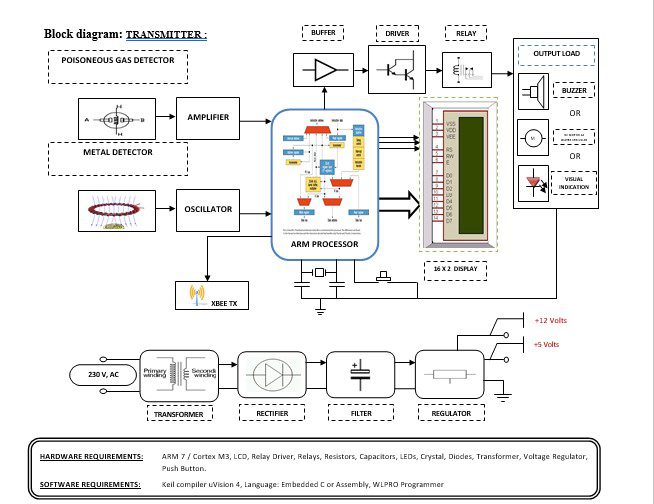

Block diagram explanation :

Power supply unit:

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

Zigbee technology:

ZigBee is the name of a specification for a suite of high-level communication protocols using small, low-power digital radios based on the IEEE 802.15.4 standard for wireless personal area networks (WPANs).

- A very low-cost, low power consumption two-way, wireless communication standard for automation, toys & PC peripherals.

- Low power consumption: 6 months to 5 years battery life for most applications.

- Low cost: At least half the cost of Bluetooth solutions.

- The high density of nodes per network: 250 nodes per network, multiple co-located networks.Data rate requirements: Few bits to 250kbps sufficient.

ARM processor:

ARM is a computer processor-based RISC architecture. A RISC-based computer design approach means ARM processors require significantly fewer transistors than typical processors in average computers. This approach reduces costs, heat, and power use. The low power consumption of ARM processors has made them very popular:

The ARM architecture (32-bit) is the most widely used in mobile devices, and the most popular 32-bit one in embedded systems.

ARM processor features include:

- Load/store architecture.

- An orthogonal instruction set.

- Mostly single-cycle execution.

- A 16×32-bit register

- Enhanced power-saving design.

Buffers:

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface.

Drivers:

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified.

Relays:

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Metal detector:

A metal detector is an electronic instrument that detects the presence of metal nearby. Metal detectors are useful for finding metal inclusions hidden within objects, or metal objects buried underground. They often consist of a handheld unit with a sensor probe that can be swept over the ground or other objects. If the sensor comes near a piece of metal this is indicated by a changing tone in earphones, or a needle moving on an indicator. Usually, the device gives some indication of distance; the closer the metal is, the higher the tone in the earphone or the higher the needle goes. Another common type is stationary “walk-through” metal detectors used for security screening at access points in prisons, courthouses, and airports to detect concealed metal weapons on a person’s body.

Gas sensor

Explosion due to gas leakage is one of the most potential hazards in mining or industry. A mixture of gas with air is explosive within the range of 5-14% by volume of gases. The Gas Sensor Modules are designed to allow an ARM to determine when a preset gas level has been reached or exceeded. The type of gas detected depends on which module you are using. Interfacing with these sensors is done through A MQ3. The sensor modules are intended to provide a means of comparing gas sources and being able to set an alarm limit when the source becomes excessive.

Methodology:

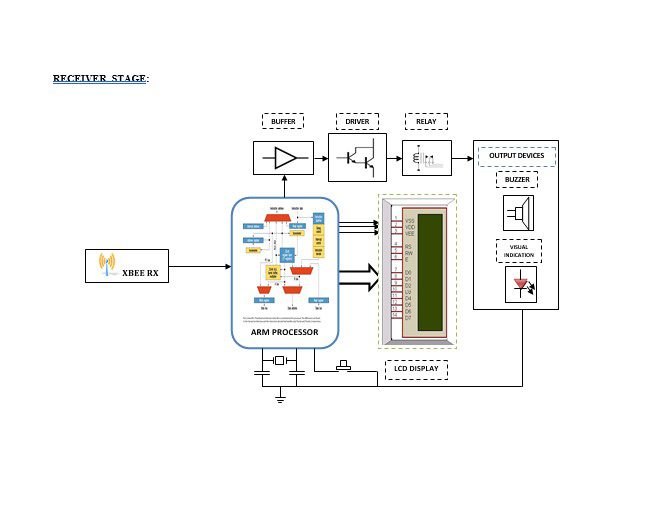

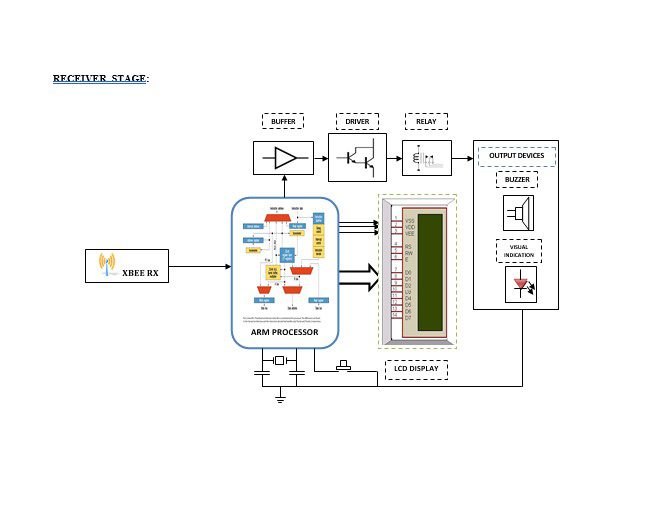

A general block diagram of the proposed scheme is given in Figure. The whole system is divided into two parts transmitter and receiver. In the transmitter part the Metal & poisonous gas Detector, when the metal or & poisonous gas is detected it gives the signal to the ARM, then the ARM will send the information to another receiving station through ZIGBEE which is in the concerned staff or security office. At the same time, ARM will generate the output that is fed to buffer IC 4050, buffer stores and given to the driver IC 2003 in driver current will amplify and voltage will invert with the help of Darlington pair circuit of driver IC to drive the relay. Then the signal is given to the output load for indication purposes.

When ARM receives the data from the Zigbee, it will enable the alert through the Buzzer on the receiver side.

Advantages:

- More useful in remote areas.

- Firing events more help full to save.

- This project we can operate Easily

- Can be used globally

Disadvantages:

- Under the mine the personal safety of staff problem.

- Personnel positioning problem.

Applications:

1. This project can be implemented in gas Industries.

2. It is used in the mining of coal & other materials.

3. It is used in municipal gas distribution.

4. This project can be used in Military applications.

5. It is used in nuclear power stations.