Table of Contents

Introduction:

Care in handling food and water is a prerequisite to ensure better health and prevention of health hazards. Foodborne illness can arise due to various reasons like improper practices in agriculture, transportation and storage of food, lack of hygiene, sanitation, and proper control mechanisms at every stage of food preparation production and consumption.

Many of the items, especially insurance spares may be required to be kept in stores for many years. It shall therefore be essential that proper methods of storage and preservation be applied so that items do not deteriorate, lose some of their properties and become unusable due to atmospheric conditions and biological elements. Economic utilization and conservation of resources and available materials, stores, or equipment are of paramount importance for the progress of the organization. Since a large number and range of items shall be stored at Corporation’s power stations, it may not be possible to lay down the procedure for the preservation of individual items. Attempts have, however, been made to cover procedures for certain important categories of materials. These are general methods of preservation and any specific instruction from manufacturers for preservation shall additionally be followed. Proper preservation shall be ensured by the storekeeper/custodian who shall work under the guidance of user departments. User departments shall also extend full cooperation in this regard and visit stores from time to time to assess implementation and advise on the matter.

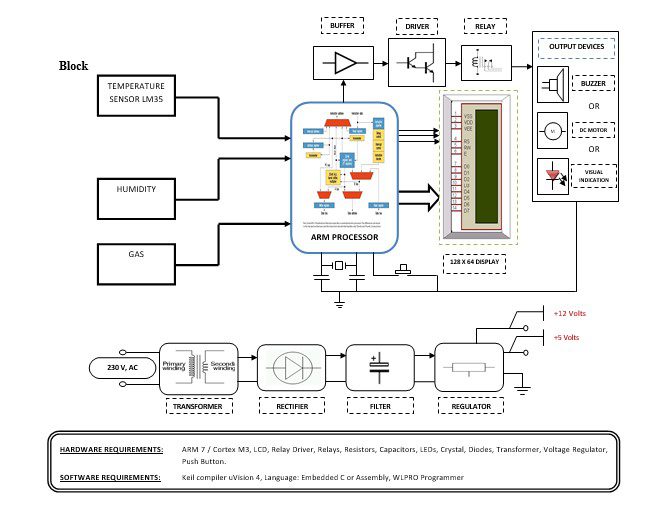

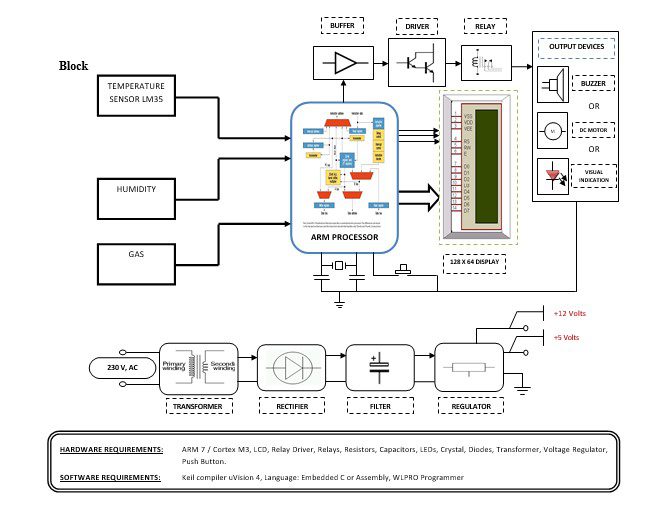

Block diagram explanation

Power supply unit

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

Temperature Sensor LM 35:

LM35 is a precision IC temperature sensor with its output proportional to the temperature (in oC). The sensor circuitry is sealed and therefore it is not subjected to oxidation and other processes. With LM35, temperature can be measured more accurately than with a thermistor. It also possesses low self-heating and does not cause more than 0.1C temperature rise in still air.

The operating temperature range is from -55°C to 150°C. The output voltage varies by 10mV in response to every oC rise/fall in ambient temperature, i.e., its scale factor is 0.01V/ oC.

Humidity Sensor:

Humidity measurement instruments usually rely on measurements of some other quantity such as temperature, pressure, mass, or a mechanical or electrical change in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices use temperature of condensation (the dew point), or changes in electrical capacitance or resistance to measure humidity differences.

Gas sensor:

A gas detector is a device that detects the presence of various gases within an area, usually as part of a safety system. This type of equipment is used to detect a gas leak and interface with a control system so a process can be automatically shut down. A gas detector can also sound an alarm to operators in the area where the leak is occurring, allowing them to leave the area. This type of device is important because many gases can be harmful to organic life, such as humans or animals.

ARM processor

ARM is a computer processor-based RISC architecture. A RISC-based computer design approach means ARM processors require significantly fewer transistors than typical processors in average computers. This approach reduces costs, heat, and power use. The low power consumption of ARM processors has made them very popular:

The ARM architecture (32-bit) is the most widely used in mobile devices, and the most popular 32-bit one in embedded systems.

Buffers

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface

Drivers

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified

Relays

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Buzzer:

A buzzer or beeper is an audio signaling device, which may be mechanical, electromechanical, or piezoelectric. Typical uses of buzzers and beepers include alarm devices, timers, and confirmation of user input such as a mouse click or keystroke.

DC motor:

A DC motor relies on the fact that magnet poles repel and unlike magnetic poles attract each other. A coil of wire with a current running through it generates an electromagnetic field aligned with the center of the coil. By switching the current on or off in a coil its magnetic field can be switched on or off or by switching the direction of the current in the coil the direction of the generated magnetic field can be switched 180°.

Indicator:

This stage provides a visual indication of which relay is actuated and deactivated, by glowing respective LED or Buzzer.

Methodology:

This project is developed to reduce the workload of human beings and to sense the parameters like Gas, Temperature, and Humidity, After sensing that parameter depending on the scenario the ARM controller will take appropriate action. The main modules in this project are Sensors (Temperature Sensor LM 35, Humidity Sensor, Gas Sensor), ARM controller unit with LCD, and output device.

This whole model is placed in Godowns. This model has three Sensors as an input device to sense the Weather condition of the Godowns and depending on the parameter measured the controller will take appropriate action. This module continuously monitors the weather condition of the Godowns. If the temperature varies, Gas detected, or Humidity varies of the Godowns, then the ARM controller will activate the buzzer to convey the information to the concerned person.

Advantages:

- All the components required are easily available.

- It is accurate [Errors are nullified] & precise as it is Digital.

- It is much more Economical compared to other analog systems.

- Manual errors can be avoided to some extent.

- Automatically controlled & Easy to use.

- Unnecessary wastage of electricity can be controlled to a greater extent.

Disadvantages:

- In this project usage of relays leads to consuming more power.

Applications:

- This project can be implemented in homes, Schools, Colleges, Companies, etc…

- Where we have to reduce the workload of humans and sense the parameters like Gas, Temperature, and Humidity there we can implement this project.

- This can be used to monitor the weather condition also.

- It can be used in industries for safety.