Table of Contents

Introduction:

Machine to Machine (M2M) refers to technologies that allow both wireless and wired systems to communicate with other devices of the same type. M2M is a broad term as it does not pinpoint specific wireless or wired networking, information, and communications technology. This broad term is particularly used by business executives. M2M is considered an integral part of the Internet of Things (IoT) and brings several benefits to industry and business [3] in general as it has a wide range of applications such as industrial automation, logistics, Smart Grid, Smart Cities, health, defense, etc. mostly for monitoring but also for control purposes.

To support the rapid new development and the worldwide adoption of the Internet of Things as well as the continued growth of M2M technology and its large-scale applications in the future, global adoption and deployment of the Internet Protocol Version 6 (IPv6) are required because all of the sensors and machine-readable identifiers needed to make the Internet of Things a reality will have to use IPv6 to accommodate the extremely large address space required. Even if the current supply of IPv4 addresses were not to be exhausted soon, the size of IPv4 itself is not large enough to support the future requirement of IoT.

Consequently, to a large extent, the future success of M2M, as an integral part of the IoT, will ultimately be determined by the successful global adoption of IPv6 in the coming years.

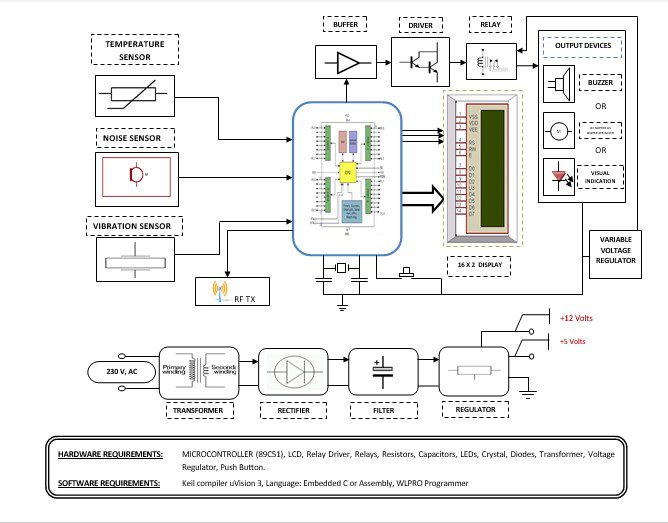

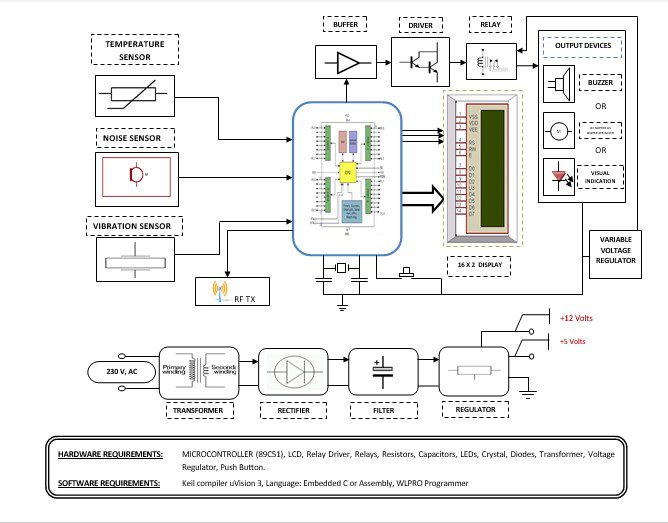

Block diagram explanation

Power supply unit

This section needs two voltages viz., +12 V & +5 V, as working voltages. Hence specially designed power supply is constructed to get regulated power supplies.

Temperature Sensor LM 35:

LM35 is a precision IC temperature sensor with its output proportional to the temperature (in oC). The sensor circuitry is sealed and therefore it is not subjected to oxidation and other processes. With LM35, the temperature can be measured more accurately than with a thermistor. It also possesses low self-heating and does not cause more than 0.1C temperature rise in still air.

The operating temperature range is from -55°C to 150°C. The output voltage varies by 10mV in response to every oC rise/fall in ambient temperature, i.e., its scale factor is 0.01V/ oC.

Microcontroller:

The Atmel AT89 series is an Intel 8051-compatible family of 8-bit microcontrollers (µCs) manufactured by the Atmel Corporation. Based on the Intel 8051 core, the AT89 series remains very popular as general-purpose microcontrollers, due to their industry standard instruction set, and low unit cost. This allows a great amount of legacy code to be reused without modification in new applications. While considerably less powerful than the newer AT90 series of AVR RISC microcontrollers, new product development has continued with the AT89 series for the aforementioned advantages.

Buffers

Buffers do not affect the logical state of a digital signal (i.e. a logic 1 input results in a logic 1 output whereas logic 0 input results in a logic 0 output). Buffers are normally used to provide extra current drive at the output but can also be used to regularize the logic present at an interface.

Drivers

This section is used to drive the relay where the output is the complement of input which is applied to the drive but the current will be amplified

Relays

It is an electromagnetic device that is used to drive the load connected across the relay and the o/p of the relay can be connected to the controller or load for further processing.

Buzzer:

A buzzer or beeper is an audio signaling device, which may be mechanical, electromechanical, or piezoelectric. Typical uses of buzzers and beepers include alarm devices, timers, and confirmation of user input such as a mouse click or keystroke.

DC motor:

A DC motor relies on the fact that magnet poles repel and unlike magnetic poles attract each other. A coil of wire with a current running through it generates an electromagnetic field aligned with the center of the coil. By switching the current on or off in a coil its magnetic field can be switched on or off or by switching the direction of the current in the coil the direction of the generated magnetic field can be switched 180°.

Indicator:

This stage provides a visual indication of which relay is actuated and deactivated, by glowing respective LED or Buzzer.

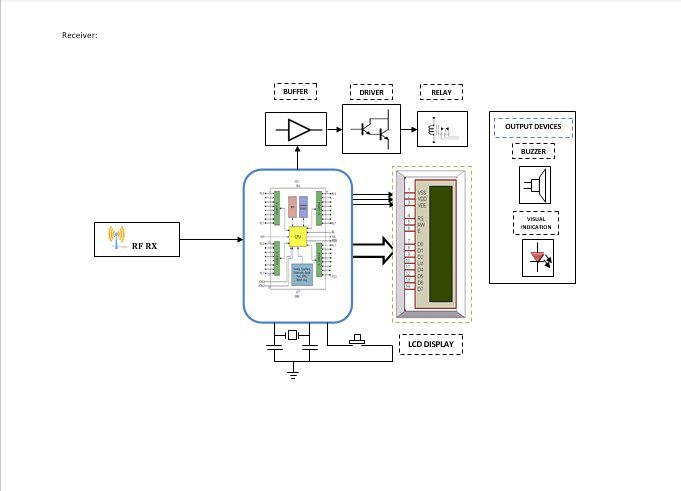

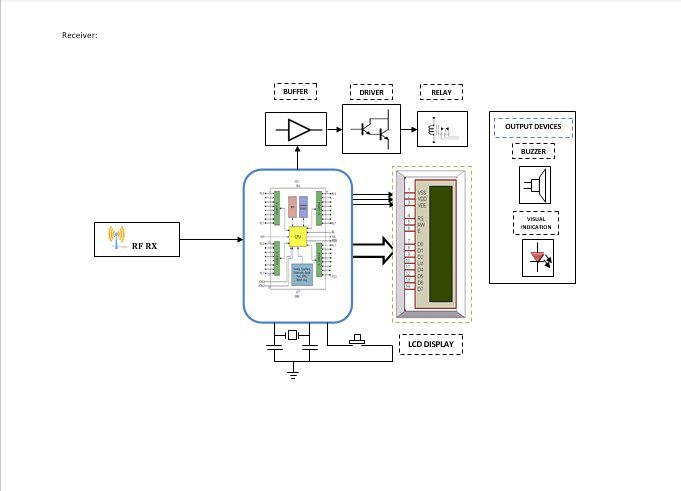

Methodology:

This project is developed to reduce the workload of human beings and enhance the machine-to-machine interaction for failure prediction using RF Transmitter and receiver technology. This project contains three sensors for Temperature sensing, Noise sensing, and Vibration sensing. After sensing that parameter depending on the scenario the Microcontroller will take appropriate action. The main modules in this project are Sensors (Temperature Sensor, Noise Sensor, and Vibration Sensor), a Microcontroller unit with LCD, and an output device.

This transmitter model is placed with machines and the receiver will be there with the owner. This model has three Sensors as an input device to sense the temperature, noise, and vibrations, and depending on the parameter measured the controller will take appropriate action. The same information will be sent to the owner via RF TX and RX. The receiver will activate the outputs to indicate a sensor has detected a signal the owner has to take appropriate action.

Advantages:

- All the components required are easily available.

- It is accurate [Errors are nullified] & precise as it is Digital.

- It is much more economical compared to other analog systems.

- Manual errors can be avoided to some extent.

- Automatically controlled & Easy to use.

- Unnecessary wastage of electricity can be controlled to a greater extent.

Disadvantages:

- In this project usage of relays leads to consuming more power.

Applications:

- This project can be implemented in homes, Schools, Colleges, Companies, etc…

- Where we have to reduce the workload of a human and enhance the machine-to-machine interaction for failure prediction there we can implement this project.

- This can be used to monitor the weather condition also.

- It can be used in industries for safety